The assignment

The Montél hocker on the right is also used as a coffee table. This is done by placing a large tray on it. The hocker is slightly convex; commercially available serving trays are flat. As a result, the tray it is unstable.

The assignment was to design a tray that can be placed stable on the hocker and that can also be used as a side table.

The design

Together with the clients we exchanged ideas about the concept. We quickly decided that the bottom of the ServingTable should follow the curve of the hocker. This makes it stable. The curve also serves as a handle.

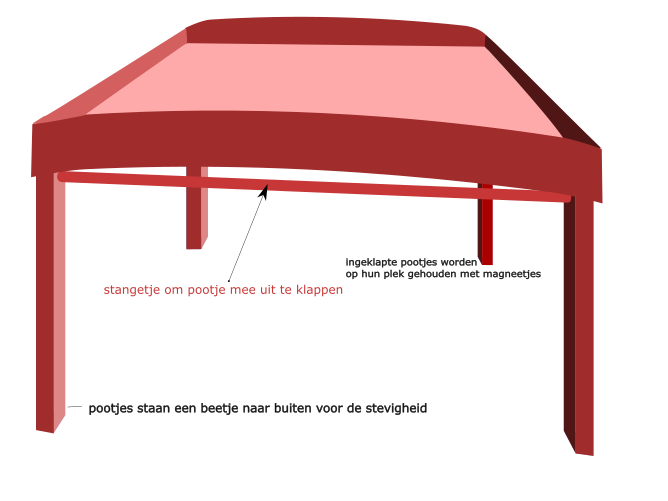

For the side table function we came up with fold-out legs, which should fit under the tray when folded so that it still stands stable on the hocker. A simple turning mechanism is placed under the tray. When you pick up the tray you can operate the rod with your fingers and fold the legs outwards and inwards.

When folded, magnets ensure that the legs stay in place. When unfolded, the legs are slightly outward for the stability of the side table.

The frame and legs of the serving table are made of mahogany. The base is a 6mm multiplex plate with cherry veneer on both sides. As much as I like making marquetry, we still chose a plain base because the top is quite large and an multi-coloured pattern would be too busy.

Mock-up uit karton

Before I put the saw in the wood, I made a 1:5 scale model out of cardboard and skewers. I used it to demonstrate the principle of the leg-folding mechanism to the clients It was nice to experience that such a model invites clients to think along spontaneously. “We could also use electromagnets, and then a pushbutton to release the legs.”

Model in MDF

To test whether and how the mechanism of folding in/out and holding with magnets works in reality, I made a model in MDF. On the left, you see the model with one leg, a part of the frame and a piece of top. At the bottom of the leg is a galvanized metal ring that also serves as a glider. I glued a magnet into a triangular block of wood and that block in turn I glued into the frame under the top – at the place where the bottom of the folded leg comes. From this I learned that the strength of the magnet and the distance from magnet to steel ring are quite critical. We also noticed that the rod that operates the folding mechanism has to be quite sturdy. We decided to use an 8mm stainless steel rod.

Milling template for the curve

To ensure that the curve of the serving table fits well on the hocker, I copied the curve on a piece of cardboard and made a milling template in MDF. To be sure, I tested the fit of the template on the stool.

The retractable legs

The magnets that catch the folded legs are concealed behind a layer of veneer. An extra wooden crossbar has been added to the legs to provide stability when folding out/in and when used as a side table.