The assignment

The Montél hocker on the right is also used as a coffee table. The owners use to place a large serving tray on it. Only, the hocker’s top is slightly convex and commercially available serving trays are flat. As a result, the tray is unstable. Not so nice if you want to serve drinks to your guests.

Mariëlle’s Meubelmakerij was requested to design a tray that can be placed stably on the hocker. Moreover, it should also serve as a side table, in a more intimate setting.

The design

Together with the clients we exchanged ideas about the concept. We quickly decided that the bottom of what we dubbed the “ServingTable” should follow the curve of the hocker to enable a stable placement. The curve also serves as a grip when the object is placed on a flat surface such as the kitchen table..

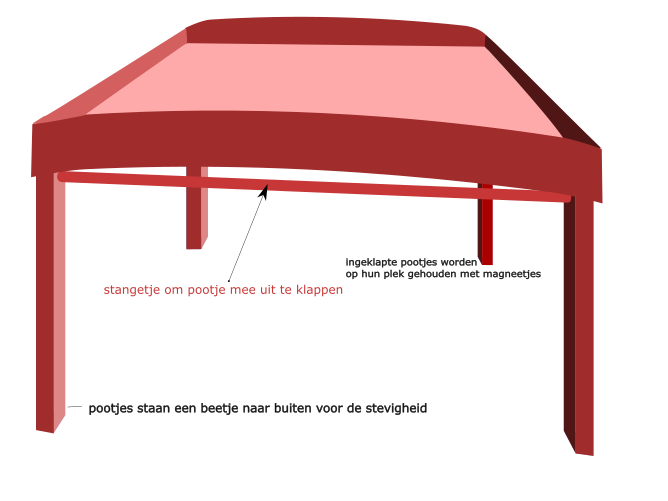

For the side table function we came up with fold-out legs, which should fit under the tray when folded so that it still stands stably on the hocker. A simple turning mechanism is placed under the tray. When you pick up the tray you can operate the rod with your fingers and fold the legs outwards and inwards.

When folded, magnets ensure that the legs stay in place. When unfolded, the legs are placed slightly outward for the stability of the side table.

The frame and legs of the serving table are made of mahogany. The base is a 6mm multiplex plate with cherry veneer on both sides. As much as I like making marquetry, we chose a plain base because the top is quite large and an multi-coloured pattern would be too busy against the multi-colored carpet.

CUSTOMER REVIEW ⭐️⭐️⭐️⭐️⭐️

“We are very happy with our experience at Marielle’s Meubelmakerij! From the very first moment it was clear that Mariëlle is not only talented, but also passionate about her profession. We had the idea of custom-made tray that can also serve as a side table and Mariëlle thought along with us in a fantastic way.

The whole process was not only professional, but also a lot of fun. Mariëlle took the time to understand our wishes and ideas and provided valuable suggestions that took the design to the next level. Her attention to detail and technical execution have ensured that the end result is not only unique, but also perfectly matches our expectations.

The material Mariëlle used is of good quality, even more beautiful than we imagined. The serving table is a very nice addition to our interior and attracts the attention of our guests every time. We can highly recommend Marielle’s Meubelmakerij to anyone who is looking for custom-made furniture of top quality!”

THE PROCESS

Mock-up made of cardboard

Before I put the saw in the wood, I made a 1:5 scale model out of cardboard and skewers. I used it to demonstrate the principle of the leg-folding mechanism to the clients. It was nice to experience that such a model invites clients to think along spontaneously. “We could also use electromagnets, and then a pushbutton to release the legs.”

Prototype of folding leg in MDF

To test whether and how the leg-folding & holding mechanism would work in reality, I made a model in MDF. On the left, you see the model with one leg, a part of the frame and a piece of top. At the bottom of the leg there is a small galvanized steel ring that also serves as a glider. I glued a magnet into a triangular block of wood and that block in turn I glued into the frame under the top – at the place where the bottom of the folded leg comes. From this I learned that the strength of the magnet and the distance from magnet to steel ring are quite critical. We also noticed that the rod which operates the folding mechanism has to be quite sturdy; therefor we decided to use an 8mm stainless steel rod.

Milling template for the curve

To ensure that the curve of the ServingTable fits well on the hocker, I copied the curve on a piece of cardboard and made a milling template in MDF. To be sure, I tested the fit of this template on the hocker.

The retractable legs

The magnets that catch the folded legs are concealed behind a layer of veneer. An extra wooden crossbar has been added to the legs to provide stability when folding out/in and when used as a side table.

Adjustment after six months

The ServingTable is being used intensively. It appeared that the mitred corners which are only glued, are is not holding. The extended legs are pressing against the bottom edges and this pressure causes the glue to release.

This problem has been solved by adding two ‘splines’ made from the same wood to each corner. An almost invisible repair and definitely more robust.